Key Performance Indicators (KPI) of an incinerator

A standard to compare different type of incinerators always apply to a specific type of waste and the price which need to be paid for consumables and for residues. Waste incinerators are mainly designed and sized on the basic charachteristics of waste :

- Calorific value of the waste (MJ/kg), mass throughput (kg/h) and size

- %Cl content in the waste (m%Cl)

- %S content in the waste (m%S)

- %N

Consumables are chemicals, like Sodium bi Carbonate, hydratated line, Caustic soda and activated carbon are the most common. But also water, diesel or gas, electricity are consumables of a waste incinerator.

Residues are directly conneted to the type of design and the strategic choose of the investor to design it. Residues mainly are :

- Bottom ash from the incinerator

- Fly as from the boiler or quench

- Fly ash from the bag house (contaminated with chemicals)

- Water purge from a wet scrubber

Residues are also price choosen.

Keeping the above conditions into account mainly for economical reasons, a good incinerator need to be designed that :

- Health and the safety of workers and people arround is guaranteed

- Unplanned downtime is minimalized

- Consumption of chemicals and production of residues is the min. possible assesment for the environment

- Min. amount of emission limit overshoot

- Productivity per shift is reaching the correct amount per shift

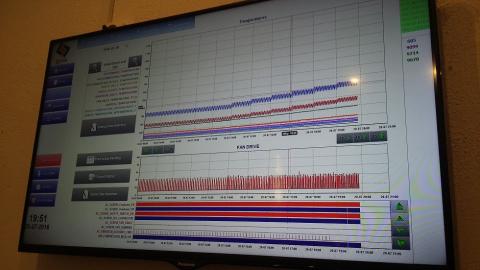

- Transparancy to the environmental autorithies